Company Advantages1. Menoir is produced under the combined theories. The knowledge of materials science and engineering, mineral engineering, and environmental science are adopted in production. The metal accessories used in its manufacturing are "Leggett Platt" branded

2. The product is able to deliver remarkable economic benefits to customers and becoming increasingly popular in the market. The product is marketed under a registered trademark namely "MENOIR

3. This product can stand up to variable temperatures. Its shapes and texture will be not easily affected by different temperatures thanks to the natural properties of its materials. It is sturdy and strong to bear

4. The product has no foul smell. During the production, any harsh chemicals are forbidden to be used, such as benzene or harmful VOC. Its production can be traced back to 1988 when the business just started

5. This product has the required safety. The Greenguard certification, a rigorous third-party certification, certifies that this product has low chemical emissions. All its wood is polished by machine

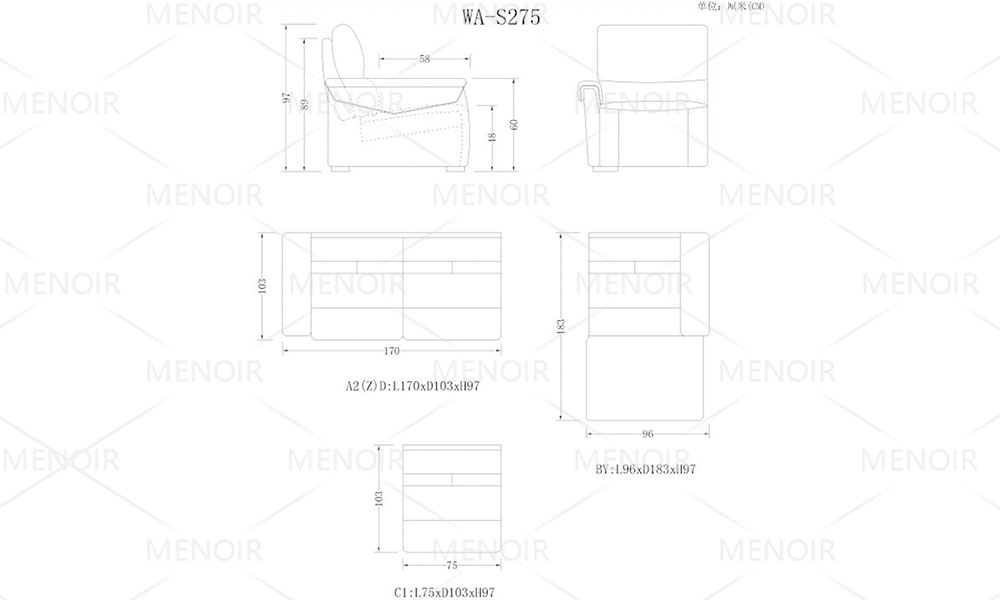

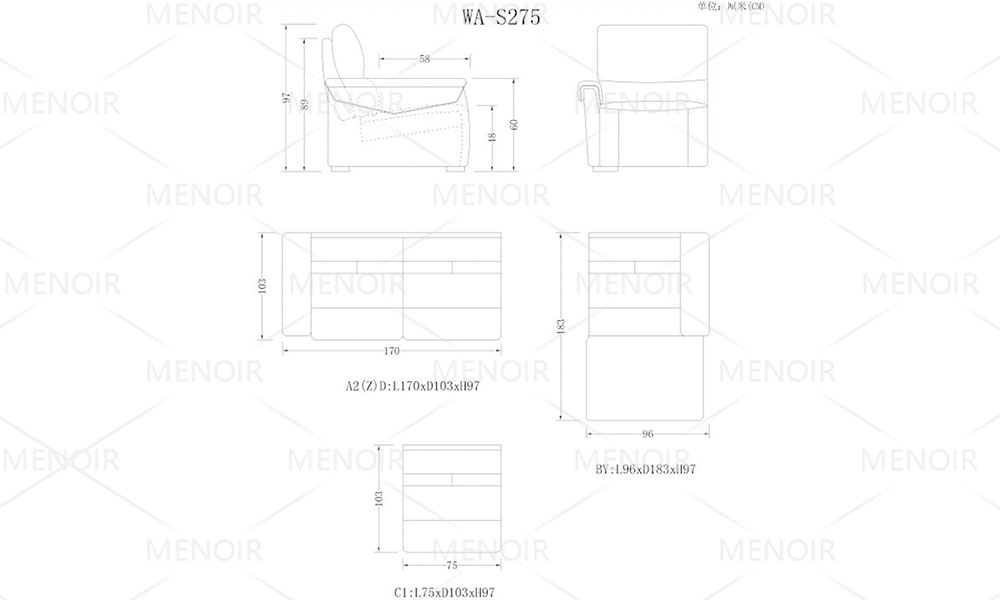

Product Name | Menoir WA-S275 Modern Leather Sofa

|

Model No. | WA-S275

|

Warranty | 1 year

|

Dimension | two seater without one arm:170*103*97cm armrest:75*103*97cm lounge:96*183*93cm

|

Material | Russia Pinewood+ plywood+high density foam+zig-zap spring+PE elastic net+polyester fiber+Leggett & Platt mechanism

|

Description | smart arm in modern style,with super comfort in seating and back cushion

|

Packaging | 1)Non-woven fabric bag 2)EPS Foam 3)Carton. (Export standard package) |

Load-ability | 18-20 sets

|

Color | Optiional

|

Application | living room

|

Wood material

1.Wood is dried to be moisture content 10%-12% which is international standard.

2.Timber size is around 4cmx3.5cm

3.All the wood need to be polished by machine after drying.

Inner Struction

1.All frames are fixed with triangle wood piece with screws and glue to make the frame more durable.

2.We use spring tie-wires to fasten the springs. Under the springs are the PE elastic net, to avoid the subsidence of sofa

3.All the blanking plates are made of 10mm thickness plywood.

4.We use import solid beech for the external frame, pinewood for internal frame.

5.The connection of frames are made by special workmanship as picture,not the nail.

Leather warehouse and cutting method

1.Store all the leather in dry place.

2. All the Italian leather need to be selected carefully and marked out with chalk before cutting, especially the scar,cowhells and other flaws.

3.Cutting leather by machine which is imported from Germany.

4.Cutting PVC and fabric by machine which is imported from Germany.

Sewing methods

1. All the sewing machine are imported from Germany, the size of strands in our factory as follow: 4/6/9/12/15/18/210/450.

2. sewing machine imported from Germany.

Foam

1. We use the high density foam for the seat cushion and back cushion, seat cushion is 35~42kg/m3, back cushion is 28~35kg/m3, some back cushion of the sofas are polyester fiber.

2. Depend on different model, we will use different density foam and we will put some feather pad inside sometimes.

Mechanism of the recliner sofas

1.All the inside function machine and metal accessory we used is from famous brand "Leggett Platt", it ensure our product stable and durable.

2.Motor is from OKIN Germany

Company Features1. Menoir devotes to concentrate on the technical innovation and optimization.

2. Continuous self-breakthrough is the guarantee for Menoir to be the leading saddle leather recliner manufacturer. Check it!