Company Advantages1. Menoir sofa leather contemporary is well manufactured. The process is carried out by our workers who handle the preparation and cutting of materials with a bar chart table and use numerically controlled lathes, saws, grinding machines. The wood used in manufacturing is dried to make sure that the moisture content is up to international standard

2. This product works as a part of the décor or either as a utility. It completes the function and beauty of the space. Exquisite craftsmanship, high grade materials and amazing details are all combined

3. This product is superior to other products because of its excellent performance, durability and other characteristics. The design is simple, with highly durable materials

Product Name | MENOIR LIGHT LUXURY LEATHER SOFA AMQ-S2019 |

Model No. | AMQ-S2019 |

Warranty | 1 year

|

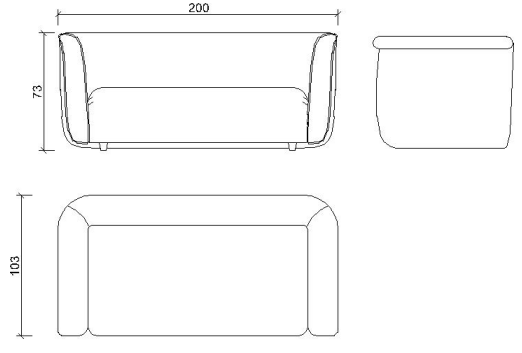

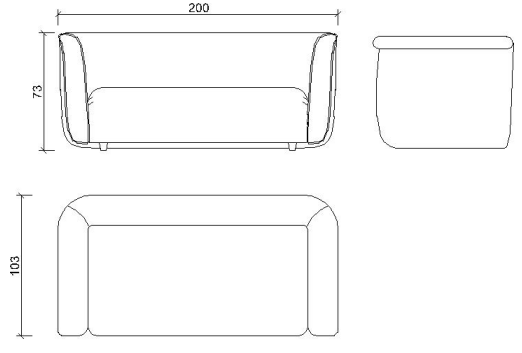

Dimension | 2seater:200*103*73cm |

Material | Russia Pinewood+ plywood+high density foam+elastic webbing+PE elastic net+polyester fiber+feather |

Description | Slim armrest and beautiful buttom-shape have a distinct design that will be both a stylish and practical addition to any home.

|

Packaging | 1)Foam 2)EPS Foam 3)Corrugated Cardboard wrapping with corner protection 4)Carton (Export standard package) |

Load-ability | 40PCS |

Color | Optiional

|

Application | Living Room Furniture

|

Wood material

1.Wood is dried to be moisture content 10%-12% which is international standard.

2.Timber size is around 4cmx3.5cm

3.All the wood need to be polished by machine after drying.

Inner Struction

1.All frames are fixed with triangle wood piece with screws and glue to make the frame more durable.

2.We use spring tie-wires to fasten the springs. Under the springs are the PE elastic net, to avoid the subsidence of sofa

3.All the blanking plates are made of 10mm thickness plywood.

4.We use import solid beech for the external frame, pinewood for internal frame.

5.The connection of frames are made by special workmanship as picture,not the nail.

Leather warehouse and cutting method

1.Store all the leather in dry place.

2. All the Italian leather need to be selected carefully and marked out with chalk before cutting, especially the scar,cowhells and other flaws.

3.Cutting leather by machine which is imported from Germany.

4.Cutting PVC and fabric by machine which is imported from Germany.

Sewing methods

1. All the sewing machine are imported from Germany, the size of strands in our factory as follow: 4/6/9/12/15/18/210/450.

2. sewing machine imported from Germany.

Foam

1. We use the high density foam for the seat cushion and back cushion, seat cushion is 35~42kg/m3, back cushion is 28~35kg/m3, some back cushion of the sofas are polyester fiber.

2. Depend on different model, we will use different density foam and we will put some feather pad inside sometimes.

Company Features1. Since inception, Foshan City Zhihao Furniture Co.,Ltd has begun to manufacture superiority cheap leather sofas . Professional quality inspection strictly controls every aspect in the production of black leather corner sofa .

2. Menoir has been optimizing its technology to keep its leather reclining sofa more competitive.

3. As a core competitiveness of Menoir, the technology of leather sectional sofa fabricating continues to be highly valued. Menoir adheres to the tenet of cultivating corporate culture always. Get price!