Company Advantages1. The manufacture of Menoir small leather accent chair adopts a variety of methods to cut and join tensile fabrics, such as advanced sail-making techniques.

2. The product is very resistant to scratches. Its anti-scratch coating acts as a protective layer which makes the countertop both more durable and safer.

3. The product is highly valued for its constantly improved performance, making it perfectly suitable for innovative and future-oriented buildings.

4. The product is most commonly used for energy storage for many electronics because it has higher cell voltage and lower cost.

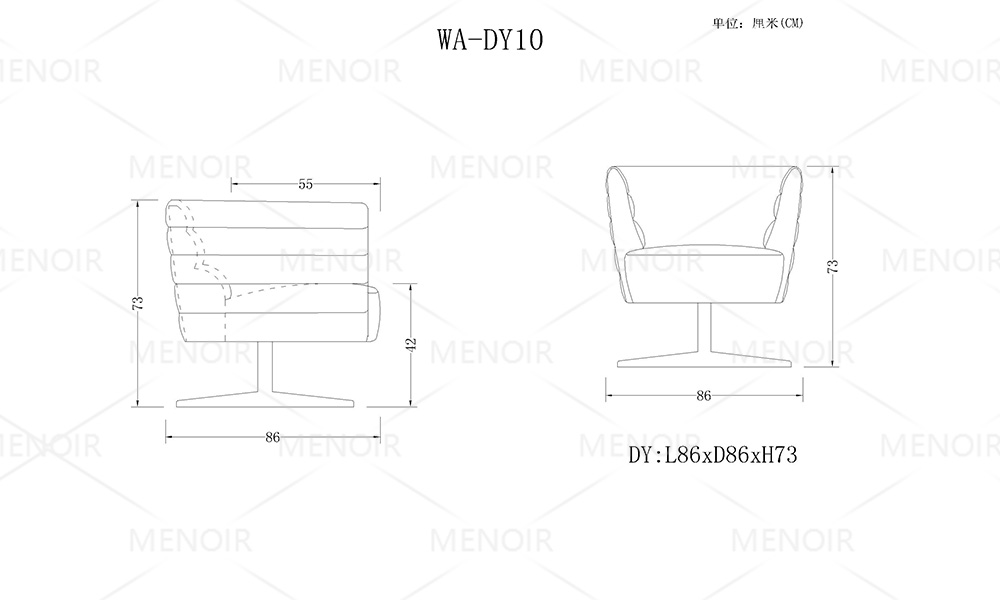

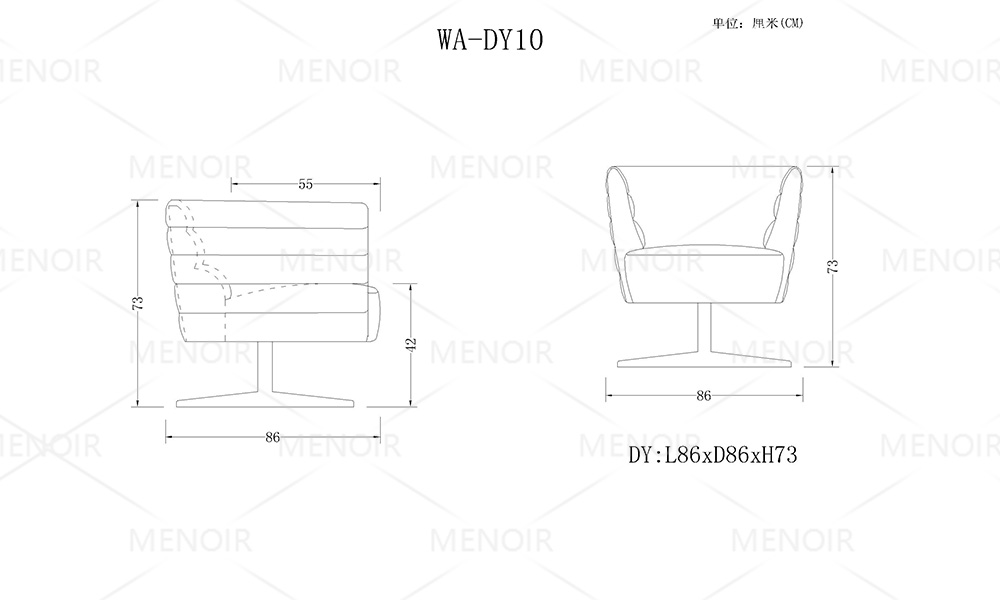

Product Name | Menoir WA-DY10 Leather chair

|

Model No. | WA-DY10

|

Warranty | 1 year

|

Dimension | 86*86*73cm

|

Material | Russia Pinewood+ plywood+high density foam+zig-zap spring+PE elastic net+polyester fiber

|

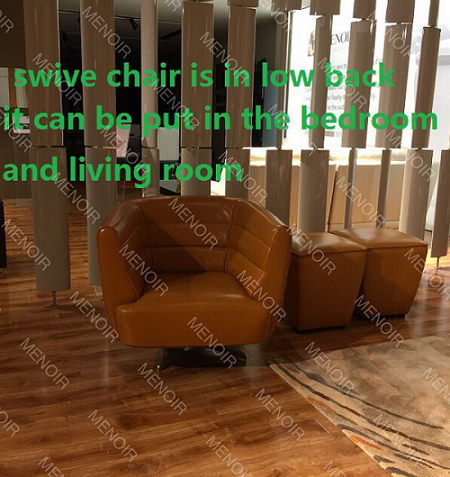

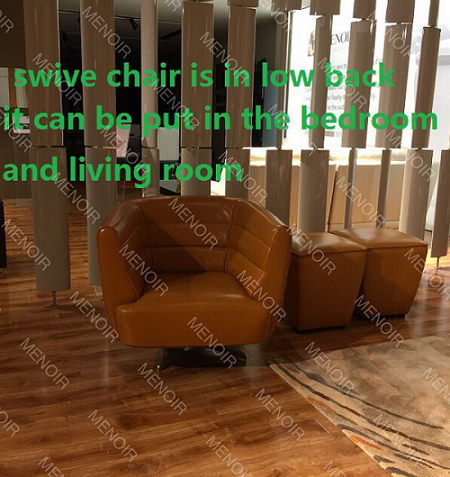

Description | 1. comfortable swivel chair.

2. cup shape design.

3. swivel base with four legs.

4. chair outside backrest with separate stitching. |

Packaging | 1)Foam 2)EPS Foam 3)Corrugated Cardboard wrapping with corner protection 4)Transparent Plastic Bag. (Export standard package) |

Load-ability | 136sets

|

Color | Optiional

|

Application | Living Room Furniture

|

Wood material

1.Wood is dried to be moisture content 10%-12% which is international standard.

2.Timber size is around 4cmx3.5cm

3.All the wood need to be polished by machine after drying.

Inner Struction

1.All frames are fixed with triangle wood piece with screws and glue to make the frame more durable.

2.We use spring tie-wires to fasten the springs. Under the springs are the PE elastic net, to avoid the subsidence of sofa

3.All the blanking plates are made of 10mm thickness plywood.

4.We use import solid beech for the external frame, pinewood for internal frame.

5.The connection of frames are made by special workmanship as picture,not the nail.

Leather warehouse and cutting method

1.Store all the leather in dry place.

2. All the Italian leather need to be selected carefully and marked out with chalk before cutting, especially the scar,cowhells and other flaws.

3.Cutting leather by machine which is imported from Germany.

4.Cutting PVC and fabric by machine which is imported from Germany.

Sewing methods

1. All the sewing machine are imported from Germany, the size of strands in our factory as follow: 4/6/9/12/15/18/210/450.

2. sewing machine imported from Germany.

Foam

1. We use the high density foam for the seat cushion and back cushion, seat cushion is 35~42kg/m3, back cushion is 28~35kg/m3, some back cushion of the sofas are polyester fiber.

2. Depend on different model, we will use different density foam and we will put some feather pad inside sometimes.

Mechanism of the recliner sofas

1.All the inside function machine and metal accessory we used is from famous brand "Leggett Platt", it ensure our product stable and durable.

2.Motor is from OKIN Germany

Company Features1. The company has a group of leather arm chairs professional and technical personnel who are in the leading position in China.

2. We are supported by professional teams. Combining with our unique technologies and processes, our exceptional in-house design, science, and engineering teams can create market-ready products designed for our customers.

3. To establish a better company image, we keep sustainable development. For example, we use less packaging and less energy to reduce production costs. We fight against climate change by our practical actions in the production. We will try to upgrade the industrial structure towards a cleaner and more environmental-friendly way.