Company Advantages1. takes the advantages of . It is built to withstand wear and tear

2. For my construction projects, this product could be an ideal solution. It is able to match my scheduled architectural styles.- Said one of our customers. The furniture expertly crafted, provides superior stability and comfort

3. The product has good temperature resistance. Even placed under the sunlight, it is not vulnerable to deform or damage. It is designed to help save space

4. The product can endure daily stressors without scratching or sustaining damage. The fingernails, sharp objects, or steel wire bush will do nothing to it. It offers exceptional comfort with a strong tolerance to wear

Product Name | MENOIR FASHIONAL STYLE AND MODERN HOME SOFA AMBO-S8033 |

Model No. | AMBO-S8033 |

Warranty | 1 year

|

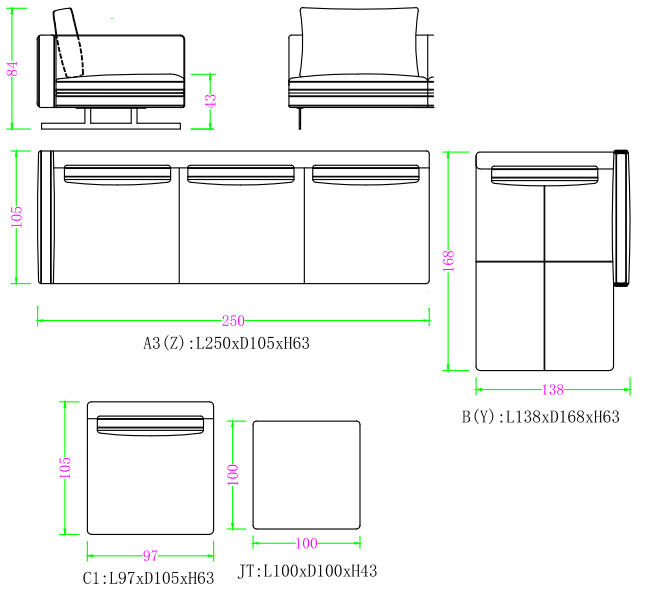

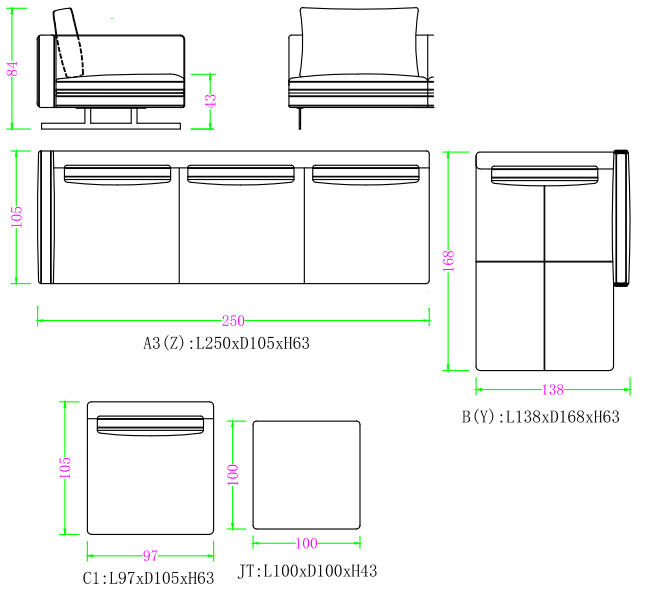

Dimension |

L shape: 388*105*63cm |

Material | Russia Pinewood+ plywood+high density foam+elastic webbing+PE elastic net+polyester fiber+feather

|

Description | 1.Seat pad in high density foam and feather together.

2. material in loose cushion is feather

3.Stainless steel legs in gray color

4.Loose cushion and seat pad

|

Packaging | 1)Foam 2)EPS Foam 3)Corrugated Cardboard wrapping with corner protection 4)Carton. (Export standard package) |

Load-ability | 28sets

|

Color | Optiional

|

Application | Living Room Furniture

|

Wood material

1.Wood is dried to be moisture content 10%-12% which is international standard.

2.Timber size is around 4cmx3.5cm

3.All the wood need to be polished by machine after drying.

Inner Struction

1.All frames are fixed with triangle wood piece with screws and glue to make the frame more durable.

2.We use spring tie-wires to fasten the springs. Under the springs are the PE elastic net, to avoid the subsidence of sofa

3.All the blanking plates are made of 10mm thickness plywood.

4.We use import solid beech for the external frame, pinewood for internal frame.

5.The connection of frames are made by special workmanship as picture,not the nail.

Leather warehouse and cutting method

1.Store all the leather in dry place.

2. All the Italian leather need to be selected carefully and marked out with chalk before cutting, especially the scar,cowhells and other flaws.

3.Cutting leather by machine which is imported from Germany.

4.Cutting PVC and fabric by machine which is imported from Germany.

Sewing methods

1. All the sewing machine are imported from Germany, the size of strands in our factory as follow: 4/6/9/12/15/18/210/450.

2. sewing machine imported from Germany.

Foam

1. We use the high density foam for the seat cushion and back cushion, seat cushion is 35~42kg/m3, back cushion is 28~35kg/m3, some back cushion of the sofas are polyester fiber.

2. Depend on different model, we will use different density foam and we will put some feather pad inside sometimes.

Company Features1. Our factory is located in the intersection of the national way, which makes transportation very convenient and cargo logistics fast. Therefore, the overall delivery time can be significantly shortened.

2. We understand that giving back is what drives us to success. We encourage employees to donate time, energy, or money to their communities, such as cleaning up parks or volunteering at homeless shelters. Get quote!