Company Advantages1. The production process of Menoir queen size leather bed covers the following stages. They are materials receiving, materials cutting, molding, component fabricating, parts assembling, and finishing. All these processes are conducted by professional technicians with years of experience in upholstery. All its materials are selected carefully to assure the quality from the source

2. This product enables people to create a unique space that is distinguished by a sense of aesthetic appeal. It works well as a focal point of the room. It offers exceptional comfort with a strong tolerance to wear

3. This product has superior quality making them compatible and versatile for the industry. It is manufactured based on imported machines such as Germany imported cutting and sewing ones

4. Our pursuit of quality makes this product better than the ordinary products on the market. It is mainly exported to the US, Australia, South Asia, Middle East, Africa, etc

5. Its quality competitiveness index has kept stabilized over the years. It is manufactured in Jiangmen production base covering an area of 300,000 square meters

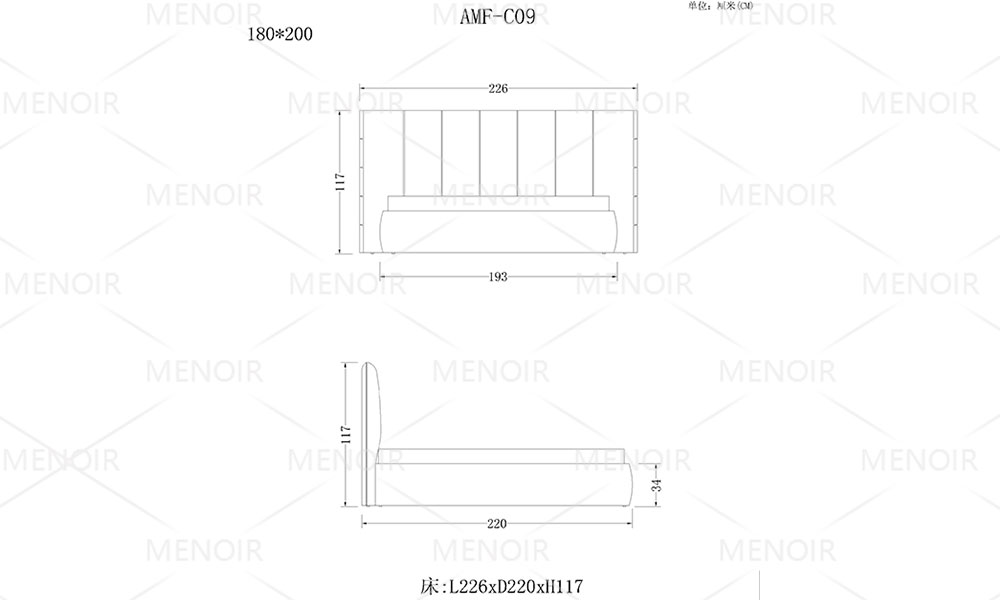

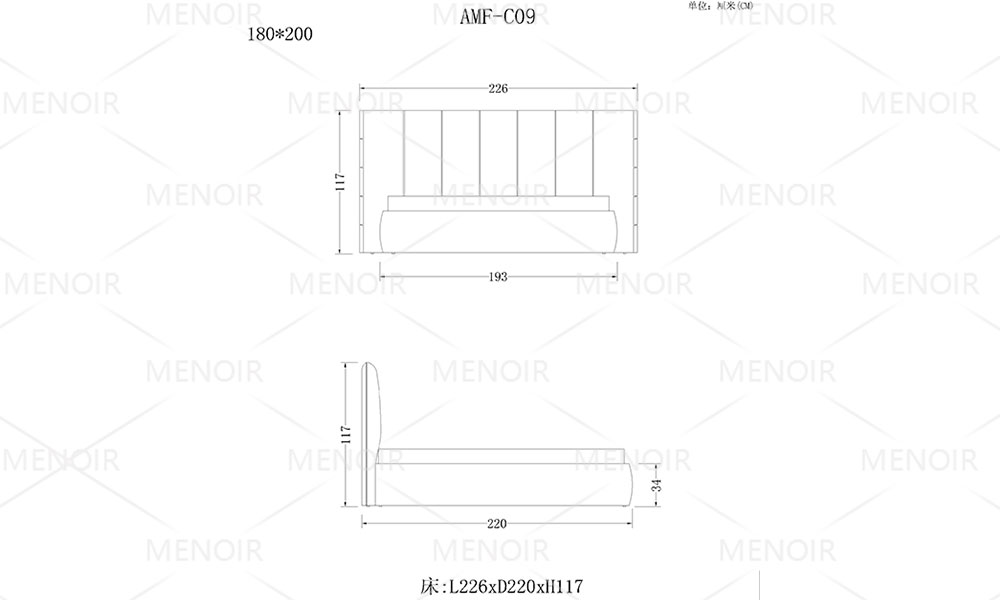

Product Name | Menoir AMF-C09 Modern Leather Bed

|

Model No. | AMF-C09

|

Warranty | 1 year

|

Dimension | 226*220*117 cm

|

Material | Russia Pinewood+ plywood+high density foam+zig-zap spring+PE elastic net+polyester fiber

|

Description | 1.Comfortable bed with high back cushion to support your head.

2. Bed can be freely combined.

3.Bed legs are stainless steel, can be knocked-down.

4.Simple modern design.

|

Packaging | 1)Foam 2)EPS Foam 3)Corrugated Cardboard wrapping with corner protection 4)Transparent Plastic Bag. (Export standard package) |

Load-ability | 34sets

|

Color | Optiional

|

Application | Bedroom Furniture

|

Wood material

1.Wood is dried to be moisture content 10%-12% which is international standard.

2.Timber size is around 4cmx3.5cm

3.All the wood need to be polished by machine after drying.

Inner Struction

1.All frames are fixed with triangle wood piece with screws and glue to make the frame more durable.

2.We use spring tie-wires to fasten the springs. Under the springs are the PE elastic net, to avoid the subsidence of sofa

3.All the blanking plates are made of 10mm thickness plywood.

4.We use import solid beech for the external frame, pinewood for internal frame.

5.The connection of frames are made by special workmanship as picture,not the nail.

Leather warehouse and cutting method

1.Store all the leather in dry place.

2. All the Italian leather need to be selected carefully and marked out with chalk before cutting, especially the scar,cowhells and other flaws.

3.Cutting leather by machine which is imported from Germany.

4.Cutting PVC and fabric by machine which is imported from Germany.

Sewing methods

1. All the sewing machine are imported from Germany, the size of strands in our factory as follow: 4/6/9/12/15/18/210/450.

2. sewing machine imported from Germany.

Foam

1. We use the high density foam for the seat cushion and back cushion, seat cushion is 35~42kg/m3, back cushion is 28~35kg/m3, some back cushion of the sofas are polyester fiber.

2. Depend on different model, we will use different density foam and we will put some feather pad inside sometimes.

Mechanism of the recliner sofas

1.All the inside function machine and metal accessory we used is from famous brand "Leggett Platt", it ensure our product stable and durable.

2.Motor is from OKIN Germany

Company Features1. As time goes by, Menoir is growing to adapt to the changes of the queen size leather bed market. We have many clients nationwide and even worldwide. We undertake horizontal and vertical integration of the industry chain resources to create comprehensive competitive advantage and build a network of regional production and global marketing.

2. The factory implements a strict quality control system to guide the whole production process. This system has helped increase the whole productivity and regulate the operation, which eventually contributes to improving product quality.

3. We have our own manufacturing plant. It has state-of-the-art machine tools to produce products of uncompromising quality. Proper equipment utilization helps us cut lead time. We will do our best to meet the needs of our customers on . Get quote!