Company Advantages1. Menoir has been given various innovative and practical designs thanks to our unremitting R&D efforts. It can be customized so as to meet different needs

2. stylish leather recliners are tasteful and have long enjoyed great fame both at home and aboard. It has been ISO14001, ISO9001 and OHSAS18001 certified

3. The product is zero-defect as we implement strict inspection on each stage of produciton process. The product is a combination of accurate design and harmonious and comfortable aesthetics

Product Name | MENOIR LIGHT LUXURY LEATHER SOFA AMQ-S2019 |

Model No. | AMQ-S2019 |

Warranty | 1 year

|

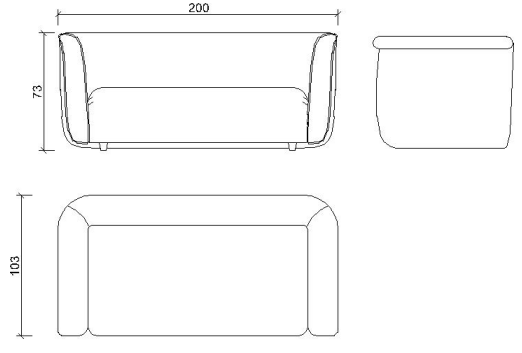

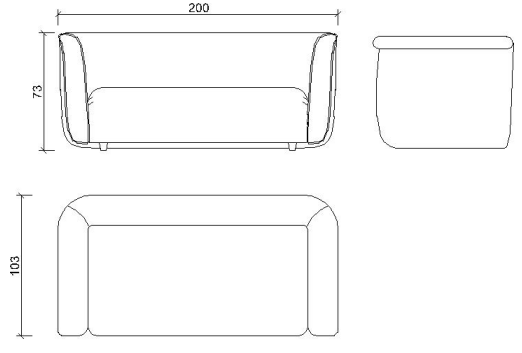

Dimension | 2seater:200*103*73cm |

Material | Russia Pinewood+ plywood+high density foam+elastic webbing+PE elastic net+polyester fiber+feather |

Description | Slim armrest and beautiful buttom-shape have a distinct design that will be both a stylish and practical addition to any home.

|

Packaging | 1)Foam 2)EPS Foam 3)Corrugated Cardboard wrapping with corner protection 4)Carton (Export standard package) |

Load-ability | 40PCS |

Color | Optiional

|

Application | Living Room Furniture

|

Wood material

1.Wood is dried to be moisture content 10%-12% which is international standard.

2.Timber size is around 4cmx3.5cm

3.All the wood need to be polished by machine after drying.

Inner Struction

1.All frames are fixed with triangle wood piece with screws and glue to make the frame more durable.

2.We use spring tie-wires to fasten the springs. Under the springs are the PE elastic net, to avoid the subsidence of sofa

3.All the blanking plates are made of 10mm thickness plywood.

4.We use import solid beech for the external frame, pinewood for internal frame.

5.The connection of frames are made by special workmanship as picture,not the nail.

Leather warehouse and cutting method

1.Store all the leather in dry place.

2. All the Italian leather need to be selected carefully and marked out with chalk before cutting, especially the scar,cowhells and other flaws.

3.Cutting leather by machine which is imported from Germany.

4.Cutting PVC and fabric by machine which is imported from Germany.

Sewing methods

1. All the sewing machine are imported from Germany, the size of strands in our factory as follow: 4/6/9/12/15/18/210/450.

2. sewing machine imported from Germany.

Foam

1. We use the high density foam for the seat cushion and back cushion, seat cushion is 35~42kg/m3, back cushion is 28~35kg/m3, some back cushion of the sofas are polyester fiber.

2. Depend on different model, we will use different density foam and we will put some feather pad inside sometimes.

Company Features1. With rich production experience, Foshan City Zhihao Furniture Co.,Ltd has become one of the leading domestic manufacturers of . The production workshop has been equipped with a variety of flexible production facilities. These facilities are manufactured with the latest technologies. This enables the workshop to meet a wide range of needs for manufacturing requirements.

2. Our factory is uniquely positioned in a place where is famous for convenient transportation, developed logistics, and a wealth of raw material resources. All these advantages enable us to conduct a quick and smooth production.

3. Our company has garnered a huge client base across the world. Without compromising the quality of the product variety, increasing market share, reasonable price, high quality and superior service with an understanding of our customers help us to retain these clients. We will continue to improve the quality of our products and services to increase our customers' satisfaction and maintain our position as the world’s leading manufacturer of high-quality products. Get info!