Company Advantages1. The entire manufacturing process of Menoir stylish leather sofa is strictly controlled. It may be divided into several important processes: the provision of working drawings, the selection&machining of raw materials, veneering, staining, and spray polishing. It is designed to help save space

2. This product is bound to help both make money and increase brand reputation. The furniture expertly crafted, provides superior stability and comfort

3. Good reliability is one of the biggest selling points of the product. The reliability guarantees consistent performance throughout the lifetime of the product. The product is a combination of accurate design and harmonious and comfortable aesthetics

4. The product has good fiber resilience. When it is pulled to a certain length for a certain time, it can still keep its original shape. The wood used in manufacturing is dried to make sure that the moisture content is up to international standard

5. The seams and seam allowances of the product are even. The advanced stitching machinery is used during the production to make sure every stitching is finely treated. The design is simple, with highly durable materials

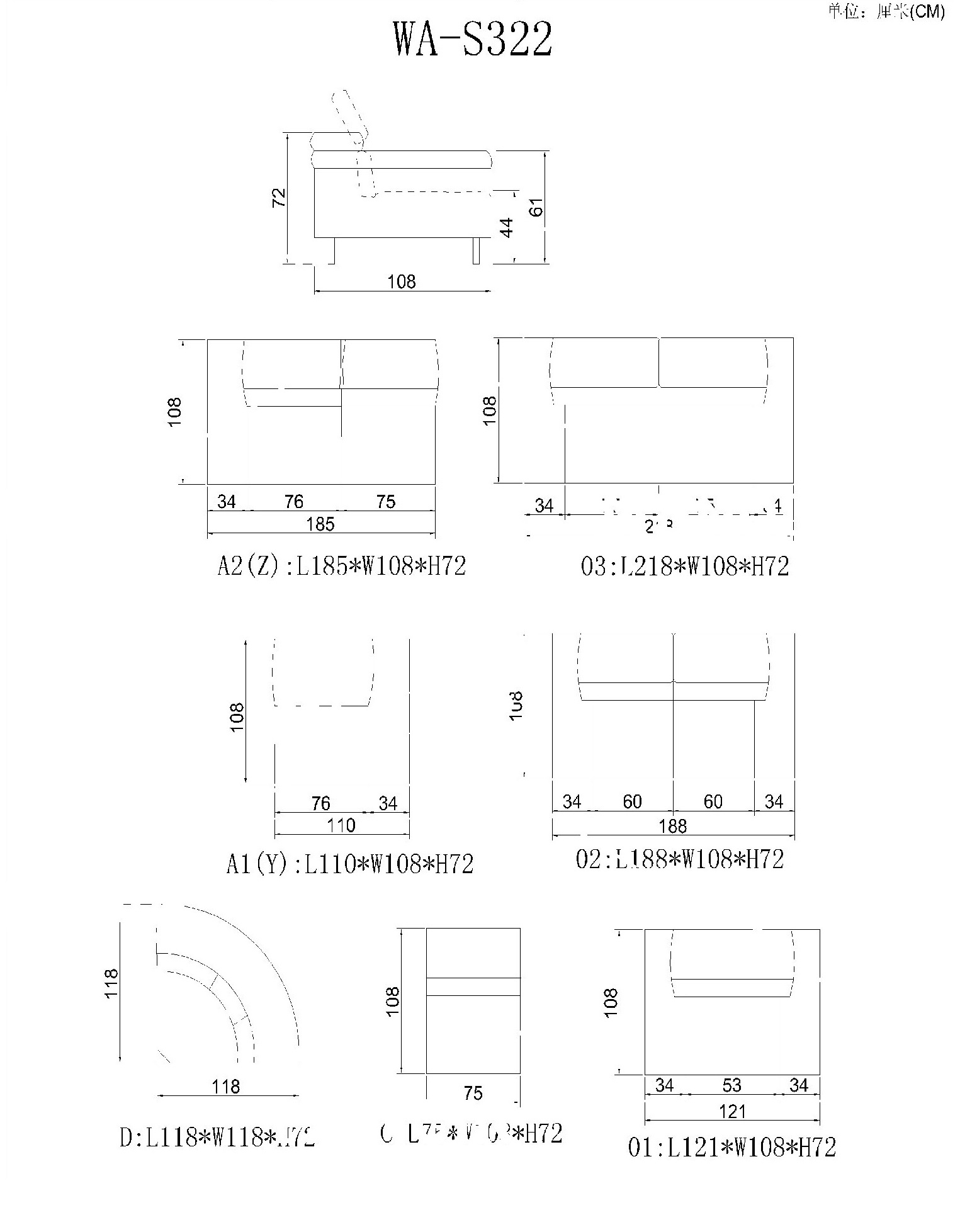

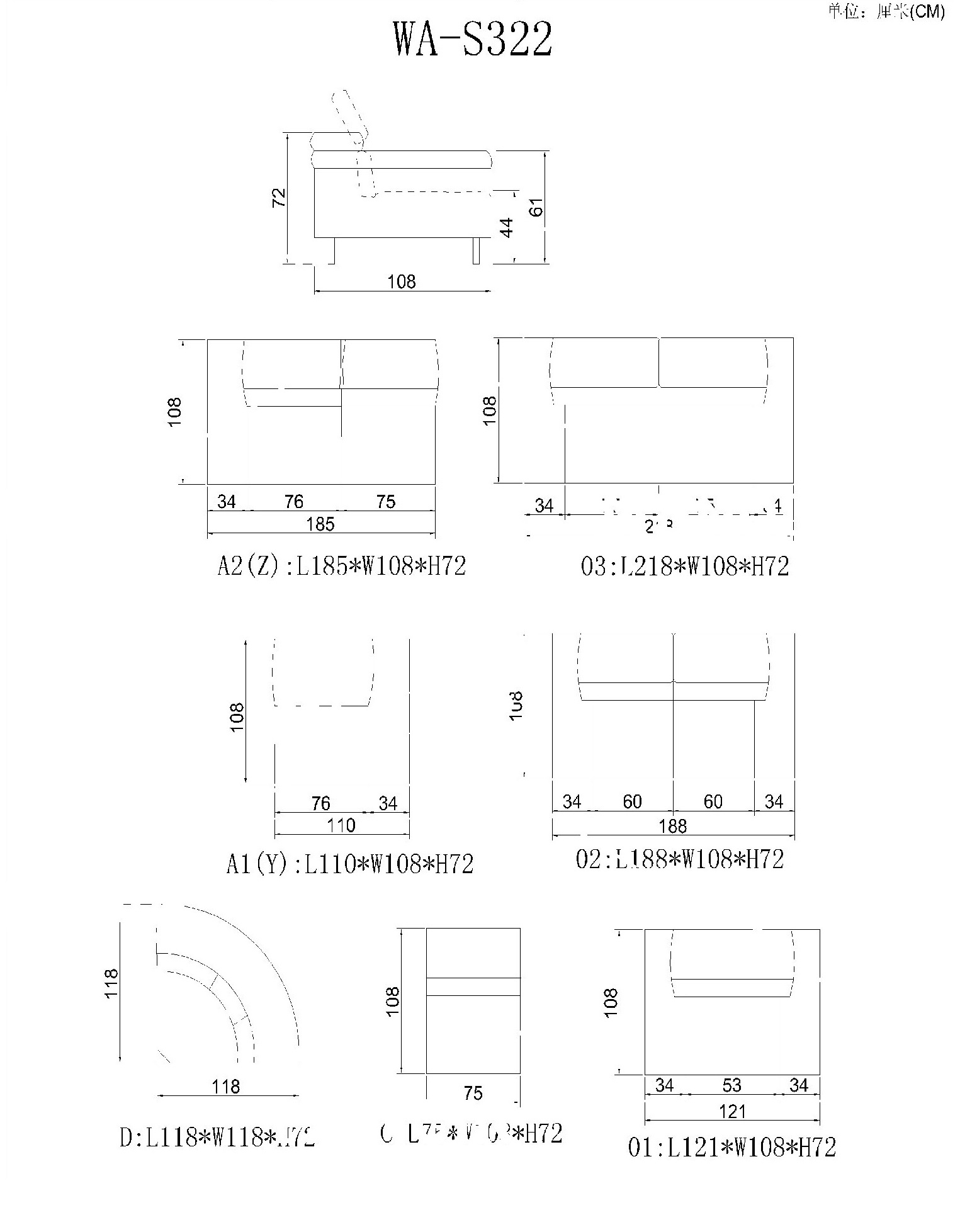

Product Name | Menoir WA-S322 Modern Sectional Leather Sofa

|

Model No. | WA-S322 |

Warranty | 1 year

|

Dimension | 303*303*72 |

Material | Russia Pinewood+ plywood+high density foam+zig-zap spring+PE elastic net+polyester fiber

|

Description | adjustable headrest keeps more comfort when seating in different angle,stylish armest under the mixture of modern and classic

|

Packaging | 1)Foam 2)EPS Foam 3)Corrugated Cardboard wrapping with corner protection 4)Transparent Plastic Bag. (Export standard package) |

Load-ability | 25sets

|

Color | Optiional

|

Application | Living Room Furniture

|

Wood material

1.Wood is dried to be moisture content 10%-12% which is international standard.

2.Timber size is around 4cmx3.5cm

3.All the wood need to be polished by machine after drying.

Inner Struction

1.All frames are fixed with triangle wood piece with screws and glue to make the frame more durable.

2.We use spring tie-wires to fasten the springs. Under the springs are the PE elastic net, to avoid the subsidence of sofa

3.All the blanking plates are made of 10mm thickness plywood.

4.We use import solid beech for the external frame, pinewood for internal frame.

5.The connection of frames are made by special workmanship as picture,not the nail.

Leather warehouse and cutting method

1.Store all the leather in dry place.

2. All the Italian leather need to be selected carefully and marked out with chalk before cutting, especially the scar,cowhells and other flaws.

3.Cutting leather by machine which is imported from Germany.

4.Cutting PVC and fabric by machine which is imported from Germany.

Sewing methods

1. All the sewing machine are imported from Germany, the size of strands in our factory as follow: 4/6/9/12/15/18/210/450.

2. sewing machine imported from Germany.

Foam

1. We use the high density foam for the seat cushion and back cushion, seat cushion is 35~42kg/m3, back cushion is 28~35kg/m3, some back cushion of the sofas are polyester fiber.

2. Depend on different model, we will use different density foam and we will put some feather pad inside sometimes.

Mechanism of the recliner sofas

1.All the inside function machine and metal accessory we used is from famous brand "Leggett Platt", it ensure our product stable and durable.

2.Motor is from OKIN Germany

Company Features1. Our company is backed by a dedicated R&D team. They have years of extensive expertise in the manufacturing industry and are able to quickly develop new products according to the newest market trend.

2. We runs the business according to the service tenet of blue leather sofa . Inquire now!