Company Advantages1. Menoir brown leather bed is manufactured by our competent workforce utilizing well-tested material and sophisticated technology following the set norms of the industry.

2. Made of quality insulation material, this product is less likely to affect by other live conductors which may lower its insulation level.

3. The product features fatigue resistance. The softener or plasticizer are used to make the mobility of the molecule strengthened, thus its anti-aging ability is improved.

4. The product helps create a relaxing bathing or washing atmosphere, representing different lifestyles. It is especially suitable for those who think highly of life taste.

5. This product provides an array of cost and sustainability benefits – it allows air to flow through and ventilate the building, permits visibility from the inside and deflects Solar Heat Gain.

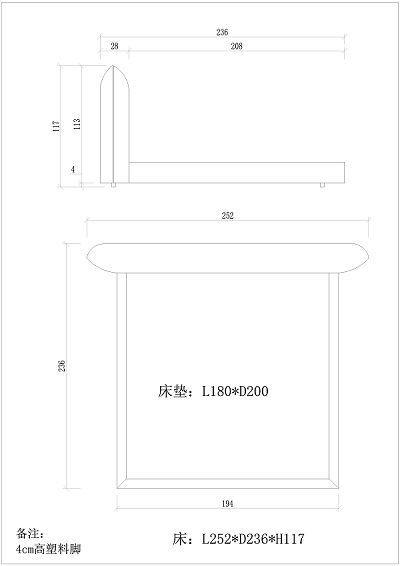

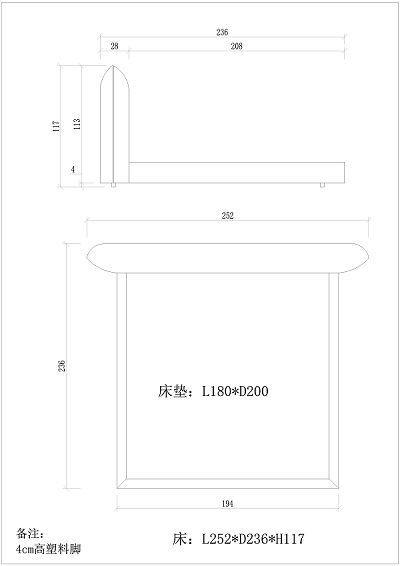

Product Name | Menoir AMBO-C8035 Modern Leather Bed

|

Model No. | AMBO-C8035 |

Warranty | 1 year

|

Dimension | 252*236*117cm |

Material | Russia Pinewood+ plywood+high density foam+zig-zap spring+PE elastic net+polyester fiber

|

Description | 1.Comfortable bed with high backrest to support your back.

2.Headboard with Stainless still in dark grey color for decor.

3. Headborad with special leather texture for beautiful style.

4.Bed leg is the stainless steel frame in dark grey color.

|

Packaging | 1)Foam 2)EPS Foam 3)Corrugated Cardboard wrapping with corner protection 4)Transparent Plastic Bag. (Export standard package) |

Load-ability | 22sets

|

Color | Optiional

|

Application | Bedroom Furniture

|

Wood material

1.Wood is dried to be moisture content 10%-12% which is international standard.

2.Timber size is around 4cmx3.5cm

3.All the wood need to be polished by machine after drying.

Inner Struction

1.All frames are fixed with triangle wood piece with screws and glue to make the frame more durable.

2.We use spring tie-wires to fasten the springs. Under the springs are the PE elastic net, to avoid the subsidence of sofa

3.All the blanking plates are made of 10mm thickness plywood.

4.We use import solid beech for the external frame, pinewood for internal frame.

5.The connection of frames are made by special workmanship as picture,not the nail.

Leather warehouse and cutting method

1.Store all the leather in dry place.

2. All the Italian leather need to be selected carefully and marked out with chalk before cutting, especially the scar,cowhells and other flaws.

3.Cutting leather by machine which is imported from Germany.

4.Cutting PVC and fabric by machine which is imported from Germany.

Sewing methods

1. All the sewing machine are imported from Germany, the size of strands in our factory as follow: 4/6/9/12/15/18/210/450.

2. sewing machine imported from Germany.

Foam

1. We use the high density foam for the seat cushion and back cushion, seat cushion is 35~42kg/m3, back cushion is 28~35kg/m3, some back cushion of the sofas are polyester fiber.

2. Depend on different model, we will use different density foam and we will put some feather pad inside sometimes.

Mechanism of the recliner sofas

1.All the inside function machine and metal accessory we used is from famous brand "Leggett Platt", it ensure our product stable and durable.

2.Motor is from OKIN Germany

Company Features1. Foshan City Zhihao Furniture Co.,Ltd is a high quality and dependable manufacturer of brown leather bed .

2. Foshan City Zhihao Furniture Co.,Ltd has state-of-art technology for modern leather bed designs .

3. We are a company with a keen sense of environmental responsibilities and a determination to follow a policy of sustainable development. Every stage of the manufacturing processes in our facilities has been studied and reassessed to see if there is any way in which it can be made more energy-efficient. Sustainability is built into the way we work. We aim at continuous quality improvement. We continuously improve ourselves by viewing the business from a “Glass Half Empty” perspective to intensely focus us on how we can stand firm in the market.